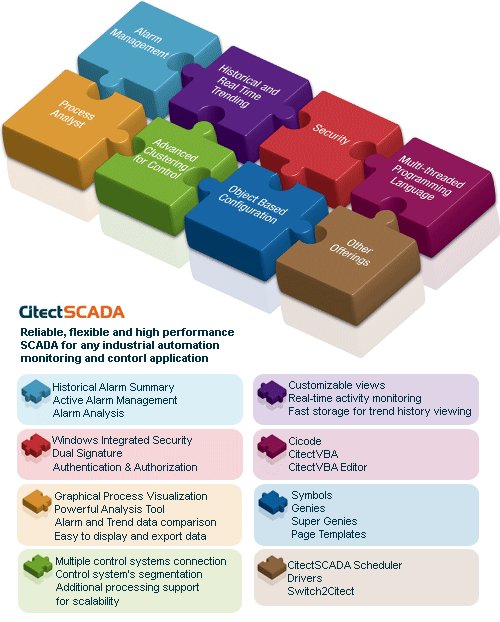

Citect SCADA

Improve product quality

Analyse and control the quality of manufactured products using standard CitectSCADA functionality, such as Statistical Process Control (SPC). Advanced statistical alarms enable your personnel to perform predictive calibration of process parameters thus preventing out of limit deviations before they occur.

Reduce your operating and maintenance costs:

Through the deployment of a centralised SCADA system, you can significantly reduce operating and maintenance costs. With fewer personnel required to monitor field equipment in remote locations, operator effectiveness is increased, and because less maintenance trips are required, maintenance and training costs are reduced.

Integrate with your business systems:

CitectSCADA can be easily integrated with your existing business systems using CitectHistorian. This historian software, with its powerful reporting tools, connects your plant and business database systems to facilitate plant-wide reporting, resulting in increased production and profitability.

Preserve your capital investment:

CitectSCADA's open system design protects against control system obsolescence and can be easily scaled to meet growing demands on your operations. Its open standards give it the flexibility to operate with hundreds of hardware and software vendors.

A secure and protected investment:

CitectSCADA is complemented by a full range of specialised customer services, including professional services, an accredited integration partner program, technical support and training, ensuring that your automation investment is secure and protected.

Enterprise access:

The web client is a zero-maintenance, fully functional client that is viewed using Internet Explorer. This web client allows all users throughout an enterprise to take advantage of real-time information by providing easy access to you SCADA system.

Powerful analysis tool:

Process Analyst is the next generation in historical visualisation tools. Unlike other SCADA systems, it allows operators and process engineers to analyse the cause of process disturbances by bringing together trend and alarm data, which traditionally have been stored separately. With Process Analyst, users can easily view them together on a single, integrated display to detect anomalies in the system.

Increase your confidence in system security:

Integration with Windows security allows corporate security standards to apply to production and creates a single location for the management of user accounts.

Increase operator efficiency and response time:

Dual signatures provides a second level of security for actions, such as those required by FDA 21 CFR Part 11.